Australia’s reliance on offshore manufacturing during the pandemic has come under the spotlight. Our dependence on overseas supplies, such as much-needed masks and vaccines, has highlighted just how little we manufacture here in Australia. Today, domestic manufacturing accounts for a mere 6% of our country’s GDP.

How the pandemic exposed our reliance on global supply chains

The Productivity Commission’s July 2021 report looked at how vulnerable our supply chains had become thanks to COVID-19. It detailed the immediate impact on logistics and transport, global surges in panic buying, and certain overseas government restrictions of exports. However, it was found that our supply chains were proving “generally more resilient”, something the business sector may disagree with, as the international shipping crisis continues.

Case in point: Australia’s reliance on China is two–way

Australia depends on China for 595 categories of goods, which we’d find difficult to import from elsewhere. For eg:, China supplies 68% of computer imports, and 100% of our manganese supply, essential for making stainless steel and other alloys.

Despite this, we are one of the few countries to enjoy a trade surplus with China, our largest trading partner, and are among one of 15 countries, including China, that forms the world’s largest free trade trading bloc.

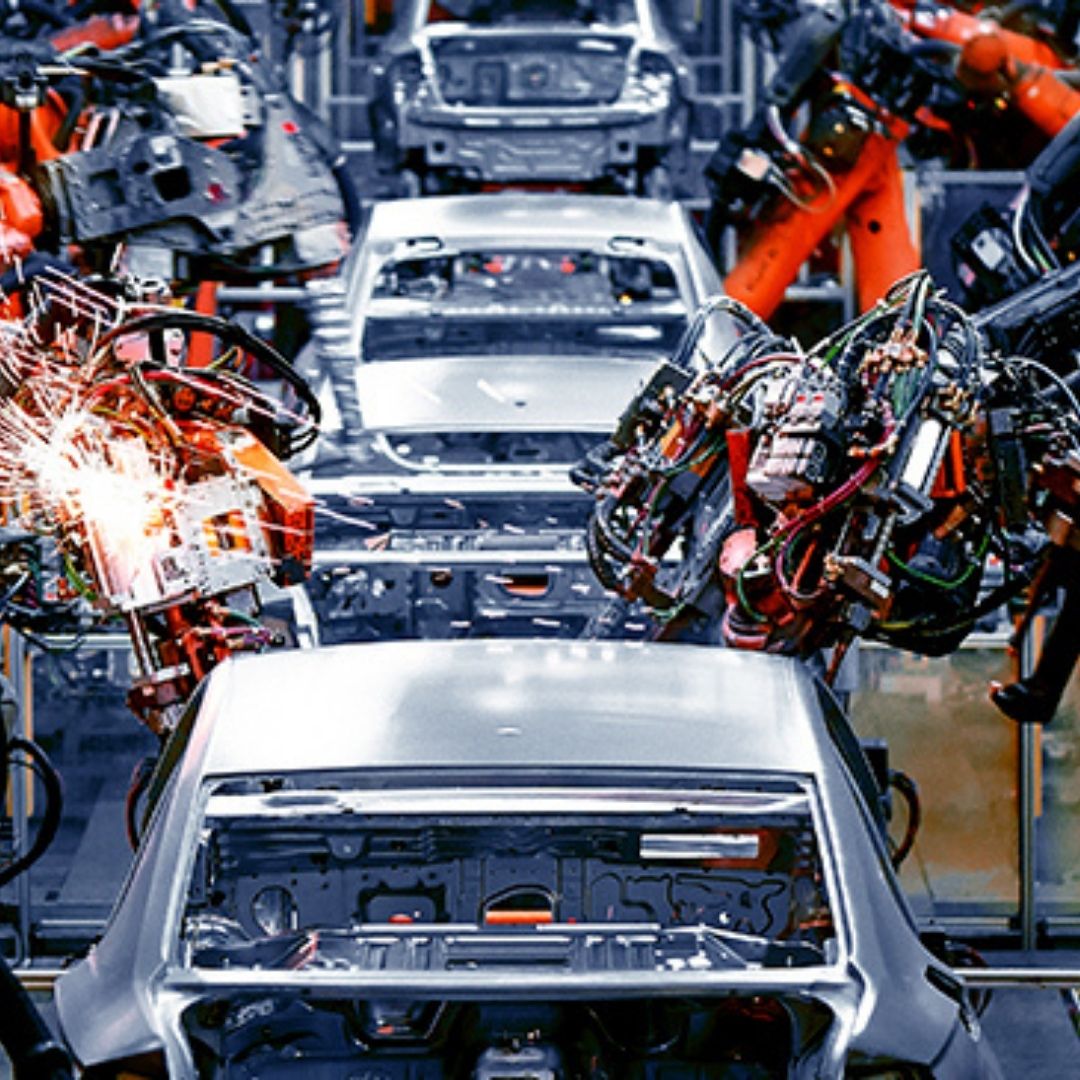

Companies bringing production back to home soil

Pandemic-induced disruptions have prompted more than half of Australian manufacturers to plan to revive or increase onshore capacity within the next two years, as they look for greater flexibility and the ability to pivot when needed.

Nearshoring – a compromise?

Another option for Australian manufacturers is to move production operations to countries closer to Australia, that is, ‘nearshore’, such as Vietnam, and Thailand. Benefits would include similar time zones and slimmer labour costs.

How to refine your risk management strategy

So, ‘right shoring’ your operations to transform your business and build resiliency against future shocks could be the future. This may entail a new suite of risks and you’ll need to consider the risk appetite of your business.

If you would like to know more about assessing future manufacturing risks, please CLICK HERE or contact us for more information.